Validation

Functional Testing

Verifies each function/feature of the software. Types are Unit testing, Sanity Testing, User Acceptance testing, Regression testing and System Testing.

Unit Testing

To validate that each unit of the software performs as designed.

System Testing

Validates the complete and fully integrated software product

Regression Testing

To ensure no new feature/bug fix has not adversely affected existing features

Sanity Testing

Performed after receiving a software build, with minor changes in code, or functionality, to Check that the bugs have been fixed and no further issues are introduced due to these changes

User Acceptance Testing

Actual users test the software to see if it is able to carry out the required tasks it was designed to address in real-world situation

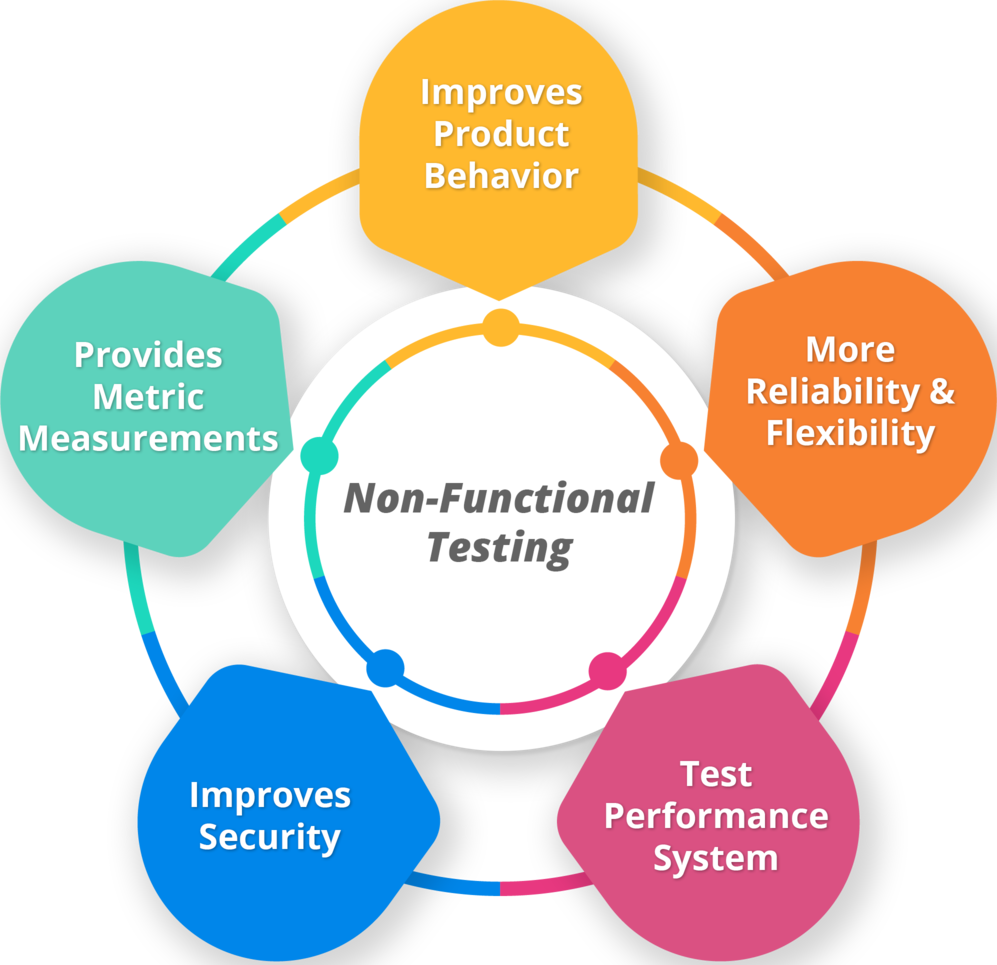

Non Functional Testing

To check non-functional aspects (performance, Security, reliability, etc) of a software application

Performance Testing

The process of determining the speed, responsiveness and stability

Security Testing

Reliability Testing

Types of Validation

Manual Validation

- Manually Convert the QR code into binary and compressed format ,Decompress on user request while navigating to manuals screen

- Manually test the firmware upgradation with custom Xmodem over Bluetooth Low energy(BLE)

- Board bringup with device drivers and BSPs

- Manually validate Alarm clearance mechanism

- Manually Test SNMP Mibs with GET,WALK and SET response of Network Device

- Secure Boot, Remote upgrade, Secured Device Onboarding (SDO), Device Management Server integration (MeshCentral)

Automation Validation

- Automate the Entire Address Space read & write of DRAM for DEV mem memory Bandwidth Validation

- Validate GUI with Multi language support (French, German, Portuguese, Dutch and English)

- Automate the Docker interfaces to initialize virtual environment for Dashboard validation

- Automate Environmental and Dashboard Initialization lunch

- Shell scripting to run driver functionalities using Cron schedule

- Test framework and GUI development

- Automate Web UI Validation

- Automated light control mechanism and Automated Panic alarms

- Automated Package installation scripts for easy installation of application server

- Automation on DSO Tool with Program manual Queries

- Automate MQTT Server ,Client and Broker Connection establishment using paho-mqtt lib package

Hardware Diagnostics

- Validate power ON/OFF conditions with Battery operations, factory settings with reset switches

- LORA Range Testing

- Voltage and current measurements on sideband signals

- Impedance Matching

- SMBus registers Read/Write operation

- Sensor calibration/validation

- Sensor calibration/validation

Protocol Validation

- USB MTP Class Integration, Bluetooth A2DP

- SSD Current measurement during Peak data transfer, PCIe/NVMe low power states - using custom daughter card.

- Pcie State machine validation with for different features like Resets, IDLE/ACTIVE modes

- USB protocol analyzers

- Validation on I2C, SPI, Ethernet

- Validation on Wi-Fi, BLE, LoRa, NB-IoT, CAT-M ,LTE , Zigbee, 6LoWPAN

- Validate http/https, telnet and SSH Protocols

Data Validation

- Testing Performance of SSD Device using IO-METER APP

- IO read/write performance using FIO

- Data capture and live streaming

Design verification

Customers benefit from the Mobiveil’s design verification process that ensures production quality hardware with lesser iterations.

- Schematic verification services

- PCB layout verification services

- Product system level verification w.r.t the requirement.

- MTBF and FEMA analysis.

Schematics Verification Services

Our customers realize the value of verification in the product development phase to ensure that the product iterations are lesser. Mobiveil has an automated methodology to verify the schematics/netlist based on Pre-defined Design rule checks.

PCB Layout Verification services

PCB Layout verification is an automated process to verify the Electrical and Physical aspects of PCB Layout. This is a process to identify potential design issues and the design violations that lead to potential SI/PI, EMI/EMC issues at the early phases of the product development. Automated tool flow integrates fast and Comprehensive rule checks to identify traces crossing splits, reference plane changes, decoupling capacitor placement, shielding issues, and via checks